Advances in computing technology have paved the way for smaller, faster, and cheaper consumer electronic devices. These advances allowed devices to become ubiquitous, significantly shaping daily life by increasing access to computational services. Whether for finding our misplaced keys via AirTags or ordering household items via Amazon Dash buttons, nowadays, even for the most mundane of tasks, there is a device for that. However, computing devices have become so deeply woven into our lives that we are primed to treat them like any other material, particularly in their disposal. With electronics so widely accessible and cheap to produce, we have even seen the rise in one-time use or disposable electronic devices (for example, digital COVID tests, digital pregnancy tests, disposable vape pens, and more). To an even larger extent is the rapid obsolescence of devices (through discontinued support, changing market trends, or the release of updated versions) that generally lead to improper disposal. In fact, according to the United Nations Sustainable Development Goals Reports, in 2019, each person generated an average of 7.3 kg of e-waste and only 1.7 kg of it was properly recycled.a Meanwhile, there was an estimated 53.6 million metric tons of electronic waste being generated that year, the world’s largest growing consumer waste stream.5 Unfortunately, this is a testament to how the rapid proliferation of new consumer technologies has not been responsibly met with advances in their recycling and disposal.

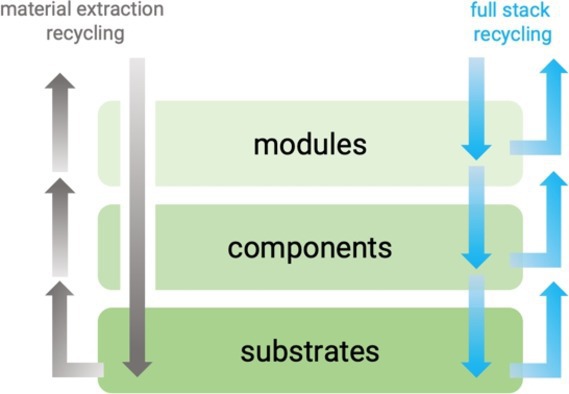

Currently, electronics recycling is primarily solved from a materials recycling approach. This is accomplished by taking the electronic device, melting it down, and extracting raw materials from it.6 Recycling plants are interested in retrieving precious metals (unfortunately often sourced from sites undergoing political conflicts, in large part shaped by resource mining3). While this method is useful for tackling recycling at large scales (that is, at the scale of large recycling plants), it can create further pollution.2,16 Moreover, the typical processes tend to focus on retrieving only a small percentage of the device material (as precious metals are the most profitable).6 Unfortunately, this recycling approach ignores the inherent functional modularity of electronic devices. In other words, electronic devices are built on a stack—unlike other waste forms (for example, utensils, packaging material, and so forth), which are typically made in a single or a few production processes rather than assembled through the combination of multiple production processes and products.

One can think about the stack of electronic devices in three layers:

Substrate: Raw materials from which the electronic components in computing devices are manufactured (for example, silicon, copper, and fiberglass);

Components: Individual electronic components which can number up to thousands per device; and

Modules: Component assemblies that are used even across very different devices (for example, power regulation, I/O systems, and microcontrollers).

Rather than tackling the recycling of electronics by treating devices as a lump sum, approaching recycling across this stack enables us to leverage the unique properties inherent to electronic design and engineering. We present an argument for a full-stack recycling approach that considers computational methods that assist with recycling at each layer rather than only once at the device’s end-of-life.

Full Stack Recycling

Electronics recycling is challenging for several reasons. Namely, computing devices are extremely diverse in design and makeup, consisting of hundreds to thousands of different components and even more diverse configurations. When coupled with the amount of (ever-growing) device types and versions that exist, it is no wonder that we have attempted to find a one-size-fits-all solution to e-waste recycling—material extraction. However, solely pursuing this one-size-fits-all solution forecloses the opportunities for recycling when we consider the similarities across electronics.

The typical electronic device contains a printed circuit board (PCB) with electronic components affixed to it. The electronic components are connected by traces on PCBs to form various circuits that enable functionality such as filtering, power regulation, or sending signals. These circuits can be very similar across devices, especially when employing standards in electronic design (microcontroller circuits, sensing circuits, power regulation, noise filtering, and so forth).b Additionally, electronic designs follow trends too. For instance, with USB-C becoming the most popular interconnecting standard, newer devices will all include subcircuits to handle being powered by or sending data across USB-C. By considering this, electronic design can be understood as organized across a stack: raw materials forming components and PCBs, components and PCBs forming circuits, and modular circuits forming the complete device.

Most recycling, on the other hand, collapses electronics into its raw materials. From this perspective, there is a single pathway for recycling: extracting the raw materials only once at the device’s end-of-life so that they can be formed into new electronic components and then formed into new circuits and then new devices again. Notably, these processes also waste much of the original device material as preserving device contents besides precious metals is resource-intensive and not economically rewarding.17

Instead, we feel a reframing of recycling electronics is necessary. Recycling electronics should be approached full stack, prioritizing how elements of electronics in each layer can be reused. By doing so, this opens a multitude of alternative circular pathways for recycling that do not require constantly starting from square one (that is, from raw materials) as depicted in Figure 1. To showcase the opportunities in approaching recycling along these layers, we go along the stack, discussing current research highlights and future research directions for developing methods of reuse on each layer.

Material Reuse. Material reuse encompasses recycling strategies for retrieving the original substrates of the device to transform them into new forms. As discussed, current recycling processes prioritize material reuse by extracting precious metals. Various advances have been made to try to improve the yield of such extraction approaches and many have argued for the economic potential in investing in “urban mining” of resources from e-waste rather than from the Earth.9,17 Companies such as Apple and Microsoft have also developed strategies to process e-waste from their products and servers such as disassembly robots and circularity centers.c,d However, there are other framings within material reuse that are often overlooked within this extraction recycling paradigm such as DIY approaches to repurposing e-waste material and integrating biodegradable electronic substrates. We highlight a few works that take such alternative approaches to reuse along the computing device’s substrate layer.

Approaches to Material Reuse. Rather than focusing on large-scale plant recycling approaches, Hanton et al. have explored how the e-ink displays in broken Kindles can be reused by crafting them into personalized low-power e-ink displays.8 Similarly, Kim and Paulos discuss examples in material reuse where often the shells of e-waste or structures of glass/metals were creatively repurposed.10 On the other hand, recent work has been exploring how electronics can be more sustainable if made from biodegradable substrates. Work from Arroyos et al. explores how a computer mouse could be designed with biodegradable materials.1 Song et. al engineers a decomposable battery.18 Koelle et al. explores how electronic components themselves can be made from biodegradable material.12 Across these cases, material reuse is prioritized, but in a way that does not rely on machines at scale for extraction recycling but instead can be done by consumers through crafty transformations or decomposition (that is, burying in the yard or dissolving in water).

Future Directions for Material Reuse. Hand in hand with material reuse are efforts to cleanly separate different materials in electronic devices. Herein lies a significant research challenge for material reuse: enabling device substrates to be easily separable for reuse. Consider, for example, decomposable electronics where copper traces can be separated entirely from a PCB.e In such a case, the device’s material makeup intentionally integrates plans for material reuse at end of life. With substrates properly separated they can be more easily reused (including with extraction recycling). On the other hand, a paradigm where device material substrates can be easily decoupled also facilitates pathways in recycling at the hands of the consumer (such as using screws instead of solder to adhere components21). Imagine a future where consumers themselves could reuse device substrates, creating jewelry from copper traces or fertilizing a garden through their decomposition. Devices no longer become useless after breakdown or obsolescence but could continue to take on meaningful forms and purposes afterwards. Moving toward this future also poses unique challenges in making the information about the material composition of devices accessible, allowing information to pass from manufacturers to the end user.

Component Reuse. A level of complexity above the substrate level are the electronic components that make up computing devices. Devices can have dozens to thousands of these components within them. Nearly all devices will contain components such as resistors, capacitors, and diodes, as they are fundamental building blocks of electronic circuitry. Most computing devices will contain microcontrollers, voltage regulators, switches, and LEDs. And increasingly, more complex integrated chips like accelerometers, photosensors, Bluetooth modules, or microphones. As shown in Figure 2, even a single-use COVID test has many complex components. Considering the complexity and utility of all these components, it is a shame that standard recycling approaches melt all these down, only to reform them back again into new components (and requiring even more resources in the process). Such approaches factor out the fact that such components often can be used as is if taken from most e-waste. We highlight current approaches toward component reuse and frame what research challenges lie ahead to make this reuse along the component layer viable.

Approaches to Component Reuse. Scavenging from electronic waste for components has recently appeared in the news as engineers and hobbyists had to contend with disruptions in supply chains during the COVID-19 pandemic.7 Many scrambled to fulfill component needs by dumpster-diving for devices that contained chips they needed (even in industry).11 Such practices point to the promise of investing in component reuse for recycling. However, tools to facilitate the process are lacking. To address this, in ecoEDA, we explored how to help engineers recycle components from e-waste during the design process, creating a tool that integrates with KiCAD (a popular electronic design software) to assist with identifying relevant recycled components that could be incorporated into their design of new projects.14 In another work, researchers in waste management explored what types of components can be reused among common e-waste and identified component testing.4 Another project has built open source hardware tools to enable the reprogramming of common chips, enabling them for reuse in new design.f These works highlight current gaps of technical infrastructure for component reuse but also showcase the many opportunities to provide support.

Future Directions for Component Reuse. Three main challenges lie ahead for enabling component reuse: identifying and inventory components, removal of components from PCBs, and testing apparatuses across component types. Such challenges can be addressed by investing in the research and creation of technical infrastructure for reuse. For instance, computer vision techniques to analyze and identify the components on PCBs (through identifiers such as footprint, labels, and so forth) could actively turn any e-waste into a resource for components. Paired with systems that automate the desoldering and testing of components, one could imagine component reuse could become viable at scale, across various e-waste devices. Such techniques would also be augmented by leveraging a library of device schematics (for example, the Open Source Hardware Association’s certified project listg) to incorporate machine learning techniques on schematics to identify component reuse opportunities. Investing in these research directions around component reuse would also help us catalog trends across component use in devices, potentially allowing us to make more informed interventions around recycling at all layers.

Modular Reuse. Last, computing devices can be understood as an assembly of various modules. These modules can take the form of individual circuits found on a PCB (as seen in Figure 2) or individual modular PCBs connected together. Each of these modules perform a certain function for the device and often, can have similarities across devices. When analyzing a device’s potential for reuse via these modules, just as components could be reused as is, whole circuits and modules could be reused as is. For instance, an engineer who would like to design with the nRF52810 microcontroller could retrieve all the compatible components (appropriate crystal oscillator, capacitors, resistors, and so forth) necessary to build out the microcontroller subcircuit. Or, consider a car charger, taken as a whole, it could be abstracted as a 12V to 5V voltage regulator module (example of this modular reuse in Lu et al.14). Analyzing devices across their modules layer enables us to find new ways to abstract the device’s parts into reusable functional blocks. We highlight a few examples of how this has been explored (both for sustainability and for consumer customizability) and future research for increasing reusability of devices along this layer.

Approaches to Modular Reuse. There are many existing examples of devices designed to be inherently modular and allow for the swapping out of modules for upgrades and customizability. For example, this is commonplace with people who build up their own PCs (interchanging graphic cards or storage) or Google’s Project Ara, which aimed to design a modular smart phone with functional modules that could be swapped according to user’s preference.h At the same time, such modular design is incredibly useful for addressing the lack of upgradability and repairability for devices that tends to lead to their disposal. Rather than trash the whole device, a more modular design might enable just switching out a module. Such is the idea behind Framework, a company invested in building a modular laptop that users can easily repair and upgrade.i They ensure a marketplace of parts, so that replacements can easily be acquired, without having to replace the entire device. Taken in a different direction, researchers have also been invested in how common e-waste devices (that is, devices that quickly fell out of trend) could be reused by taking advantage of their main functionality. For instance, there has been research on using discarded hoverboards to create moving robots15 as well as repurposing old smartphones as a server.19 Across these cases, framing devices as modular entities widens the reuse potential and preserves key functional elements of devices.

Future Directions for Modular Reuse. This concept of modular reuse can be taken further by investing in research around modular engineering. Consider, for example, if at end of life, a device’s modules could be reappropriated for another use (that is, not just for use in another modular laptop but when upgrading another interactive system). To do so would require the development of module standards in computing systems and might require changing our expectations of computational devices. Overall, the trend in electronics engineering has been to make things smaller and more tightly packed. While this has enabled highly mobile, ubiquitous devices, this makes them inherently harder to reuse on a module level. Modular design’s need for robust connectors (to allow their swapping in/out) is at odds with extremely small devices. Similarly, software protocols that can anticipate and be flexible toward these modular, interchangeable connections will need to be developed. However, considering strategies for making modules removable and interchangeable would significantly shift how reusable, upgradable, and repairable devices are, potentially with dramatic consequences to reducing our e-waste production.

Reuse Across Stakeholders

In addition to preserving functionality across the stack, a clear advantage we see in pursuing full stack recycling over extraction recycling is that it empowers a wider scale of stakeholders in participating in the recycling process. The current paradigm of recycling primarily allocates responsibility to manufacturers and recycling companies. On the other hand, pursuing full stack recycling affords opportunities for engagement from others too. This includes the designers and engineers who can more intentionally create devices with reuse in mind whether it is enabling substrates to be more easily separable, well-labeled, and retrievable components, or employing more modular design strategies. It also includes repair technicians who would be afforded more strategies for repair given the ability to upcycle components or take relevant modules from other devices (another key pathway for sustainable computing). And finally, it empowers consumers to engage in what is inside their devices, how they could reuse them, and how they can responsibly recycle them.

Empowering end consumers is particularly key for the issue of e-waste for a few reasons. A recent study that looked at the contents of e-waste in a municipal waste stream showed 36.2% of the devices had could have been immediately reused, while an additional 9.5% required only minor repairs.20 Even if devices were not broken or could be repaired, they were sent in as e-waste recycling, emblematic of a culture where consumers default to extraction recycling rather than seeking out reselling or repairing as alternative pathways. This becomes even more contentious when considering how difficulties in defining what is and is not e-waste. In fact, legal debates around e-waste policy have even interpreted e-waste as determined by the consumer and when they decide their device becomes waste.13 Additionally, the cost of changing business and manufacturing structures toward more sustainable directions is a significant inhibitor, and one that companies are unlikely to take on unless driven by consumer demand. Given this, it is unfortunate that our current recycling regime does not provide opportunities for consumers to truly engage with recycling strategies whether through understanding what makes up their computing device or knowing various options for recycling. Full stack recycling approaches can close this gap by building recycling pathways to be more accessible to consumers.

Last, full stack recycling allows for a much more resilient computing ecosystem. Rather than relegate post-processing of e-waste to recycling plants, with more empowered actors involved in shaping e-waste recycling, we can widen the sources we draw from to support our computing infrastructure and lessen our dependence on global supply-chains. As discussed, frugal scavenging approaches were necessary when the pandemic disrupted supply chains. Building out infrastructure to make full stack recycling viable across all stakeholders would enable resilience in the face of disasters (that is, climate change, infrastructure collapse, and so forth). Just as we think about how to make computing infrastructure resilient to such events, we should explore how our recycling approaches can be similarly resilient.

Conclusion

To pursue more sustainable futures of computing, it is imperative that we address the massive amounts of e-waste being generated alongside advances in computing technology. Frankly, our recycling paradigm has not evolved to keep up with the immense amount of e-waste generated. We believe that pursuing a full stack recycling approach is necessary to preserve usefulness on each layer of the stack, broaden participation in electronics recycling, and improve the resilience of our modern computing infrastructure. We need diverse approaches along the stack that address the various scales and stakeholders at which recycling can occur. Reframing the problem of e-waste recycling as needing a full stack approach also invites the computing community to shape how devices in our ecosystem are made and unmade toward more sustainable ends. We believe incredibly interesting technical challenges are opened with full stack recycling and hope to see more approaches to facilitating reuse along the stack.

Join the Discussion (0)

Become a Member or Sign In to Post a Comment